3D Bioprinting

with 3D bioprinting you can create three-dimensional structures using biological materials using specialized printers to deposit layers of bio-inks, which are composed of living cells, biomolecules, and biocompatible materials

3D Bioprinting

With 3D bioprinting you can create three-dimensional structures using biological materials using specialized printers to deposit layers of bio-inks, which are composed of living cells, biomolecules, and biocompatible materials

Facility managers Dr. Martina Piccoli, Dr. Anna Maria Tolomeo

The Institute 3D bioprinting facility helps researchers in approach the use of 3D printing and bioprinting for their research.

What you can do with us

- 3D cell cultures

- Organ-on-chip

- Tissue model & engeneering

- Drug delivery systems

- Soft robotics

Why choosing us

- Full support from experimental and technical design with our bioengineering team to post-production management.

- Access to the IRP capabilities and know-how in 3D in vitro model production and analysis

Our instruments portfolio

CellInk BioX bioprinter

a complete standalone system that gives users great flexibility with exchangeable printheads and features. The BioX is capable of fabricating constructs containing any type of cells, enabling the fabrication of a wide range of tissue targets.

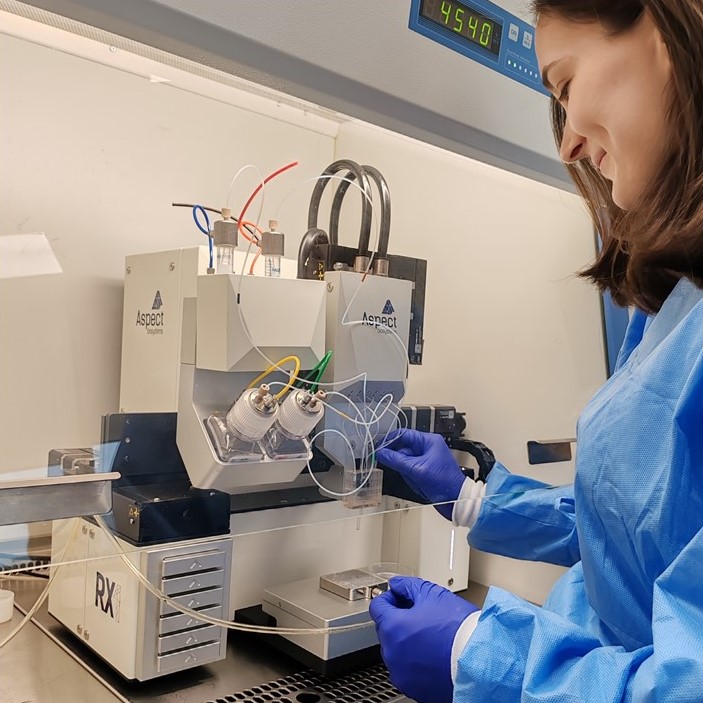

RX1 Bioprinter

a microfluidics-based bioprinter that empowers tissue regeneration by:

- rapidly switching and patterning – precise placement of cells and biomaterials;

- using fibers as building blocks – microfluidic printheads extrude hydrogel fibers that can mimic features and structure of native tissue;

- bioprinting multicellular structures – inclu sion of supporting cells, such as stromal or endothelial cells, can enhance the ability of a bioprinted therapeutic to promote tissue regeneration.

FormLab3B+ printer

able to print a variety of surgical instruments and medical devices.

This printer is suitable for:

- small to medium-sized parts requiring biocompatibility and sterilization compatibility;

- medical device prototypes, jigs, fixtures, molds, and end-use parts;

- custom anatomical models and surgical instruments for patients;

- visual aids for diagnostic and educational purposes;

- surgical planning models for diagnostic use within FDA-approved workflows;

- specialty materials research and development.